Magnetic slide conveyors for safe, jam‑free handling of ferrous parts.

Magnetic slide conveyors for safe, jam‑free handling of ferrous parts.

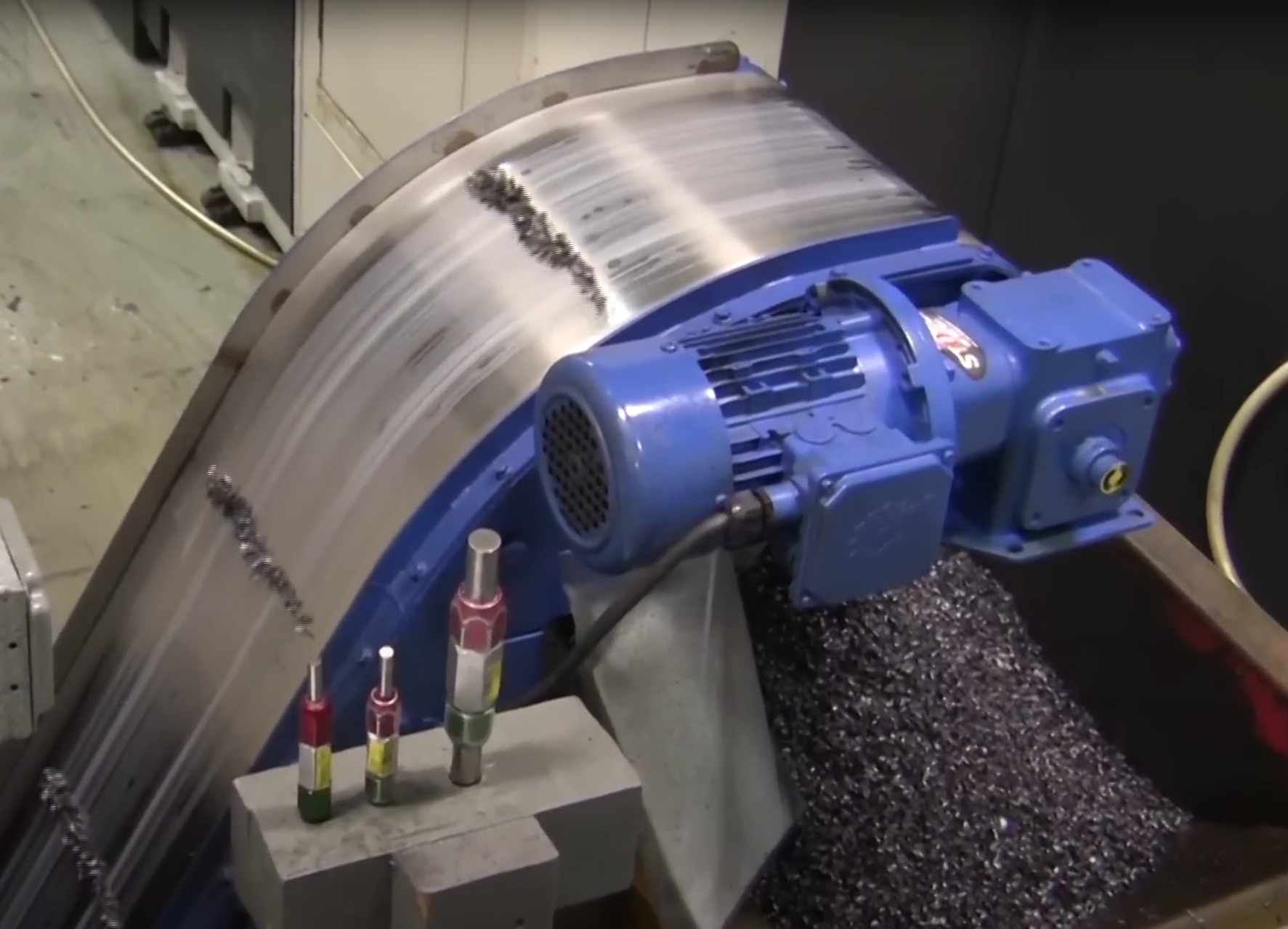

Cinco Industries represents Storch Magnetics for beltless magnetic slide conveyors engineered to move hot, cold, wet, oily or dry ferrous materials—safely and reliably. Powerful permanent magnets travel beneath a stationary slider plate to carry chips, stampings and small parts—without exposed moving components—helping you reduce jams and improve uptime.

Applications include machining chips, trim stock, small turnings, press room scrap and part transfer into assembly lines.

Ferrous material drops onto the receiving end. Magnets moving under a fixed UHMW slider plate carry the load to discharge; as magnets turn away at the head, parts release cleanly.

*Typical; actual results vary by application.

Ceramic (standard) or optional neodymium magnets, oversized solid‑pin roller chain with spring‑loaded take‑up, and fully enclosed one‑piece housings with oil‑bath lubrication for long service life.

Modular, standardized components allow tailoring lengths, widths, inclines, load ratings and infeed/discharge geometry. Storch will also fit conveyors to existing equipment and floor plans.

Choose from low‑profile and heavy‑duty series with multiple styles (A, B, C, D, D1, bi‑directional) and standard widths. Non‑standard widths and special engineering are available on request.

300 Series

Low‑profile for small stampings/parts and light scrap; standard widths 6–12 in.

500 Series

Most common profile for heavy service; widths 8–18 in (20–24 in with engineering).

800 Series

Heavy‑duty with stainless track standard; widths 12–30 in (32–36 in with engineering).

1100 Series

Largest standard profile; widths 18–42 in.

We pair your process know‑how with Storch’s beltless technology to build safer, cleaner material flow around presses, machine tools and assembly operations—delivered on timelines that keep production moving.

More about usFully enclosed drives mean fewer pinch points and cleaner operation.

Modular construction adapts to your equipment and floor layout.

Engineered for longevity—oversized chain, large sprockets, oil‑bath lubrication.

“Beltless magnetic conveying helps eliminate jams and unplanned stops in oily chip applications.”

Oversized solid‑pin chain, floating magnet attachments and spring‑loaded take‑ups maintain smooth motion under load. Enclosed housings keep contaminants out while oil bath lubrication reduces internal wear.

Ideal for chips and scrap in machining centers and stamping cells, and reliable for part transfer where traditional hinge‑belt designs struggle with fines, oil and tight radii.

Talk to us about widths, infeed heights, discharge geometry, cleat pitch and magnet selection to match your material and rate.